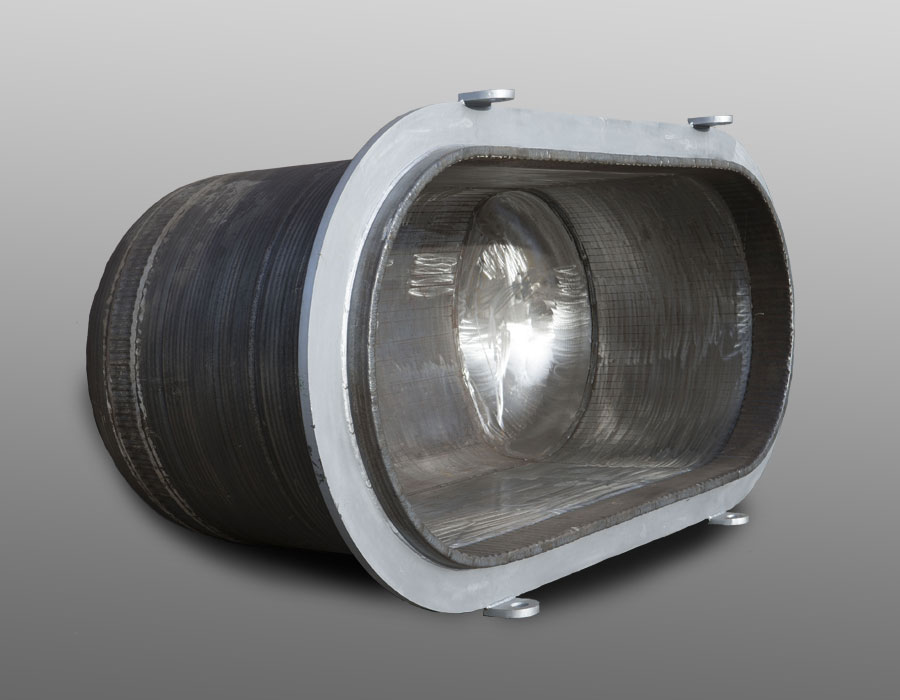

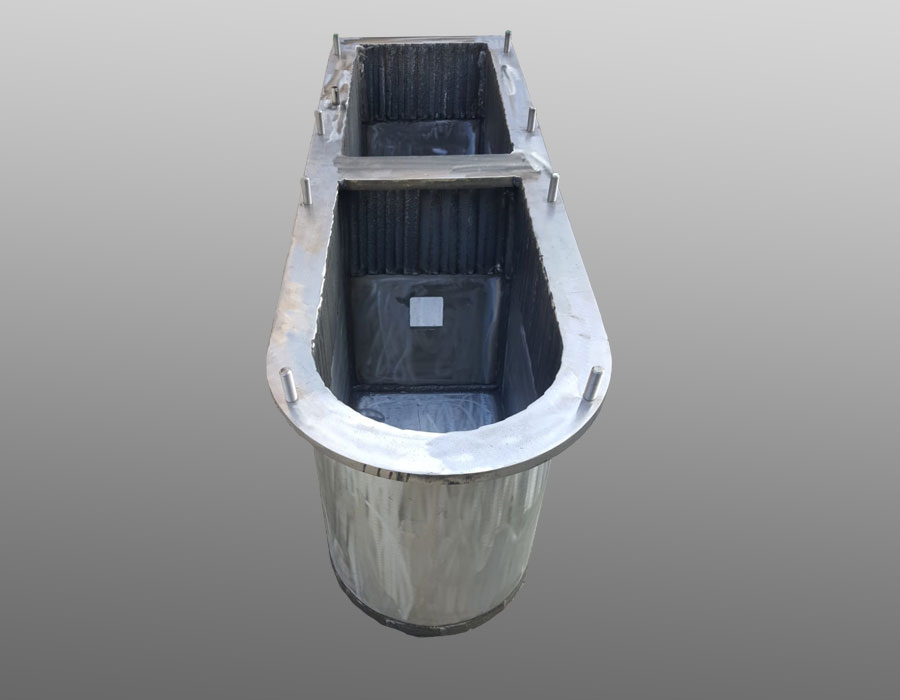

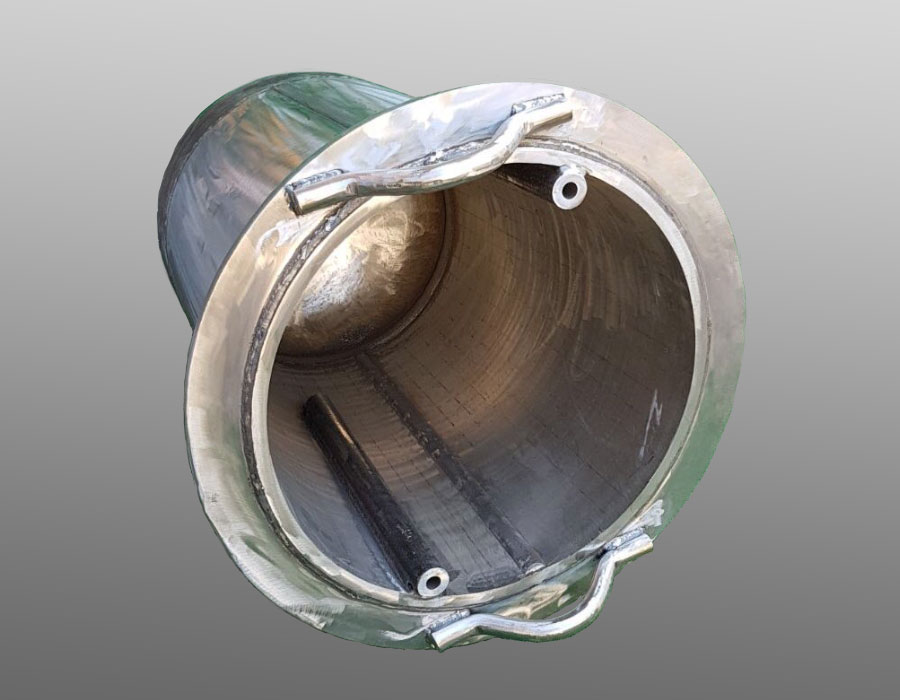

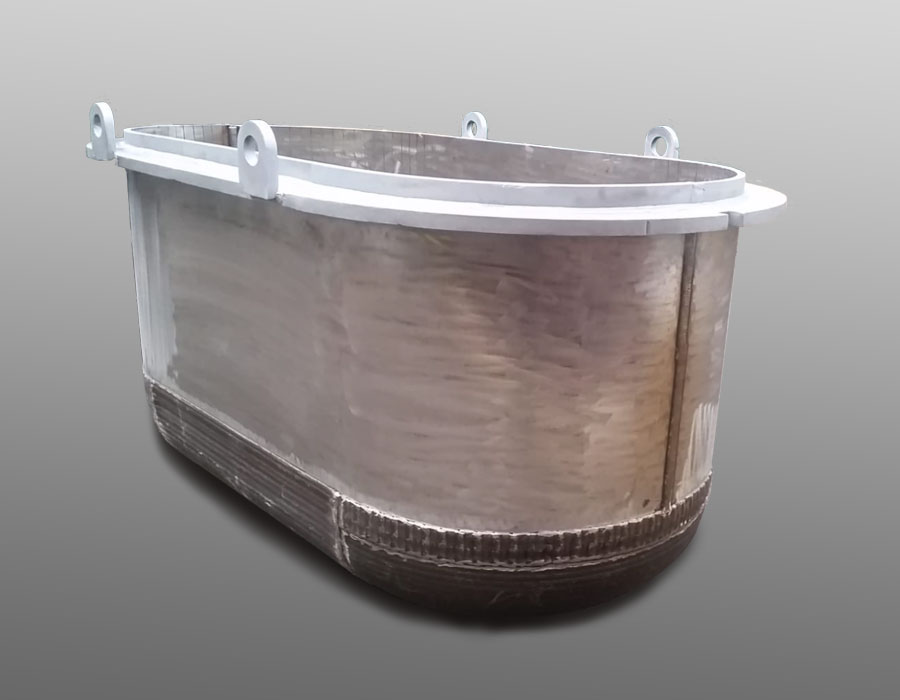

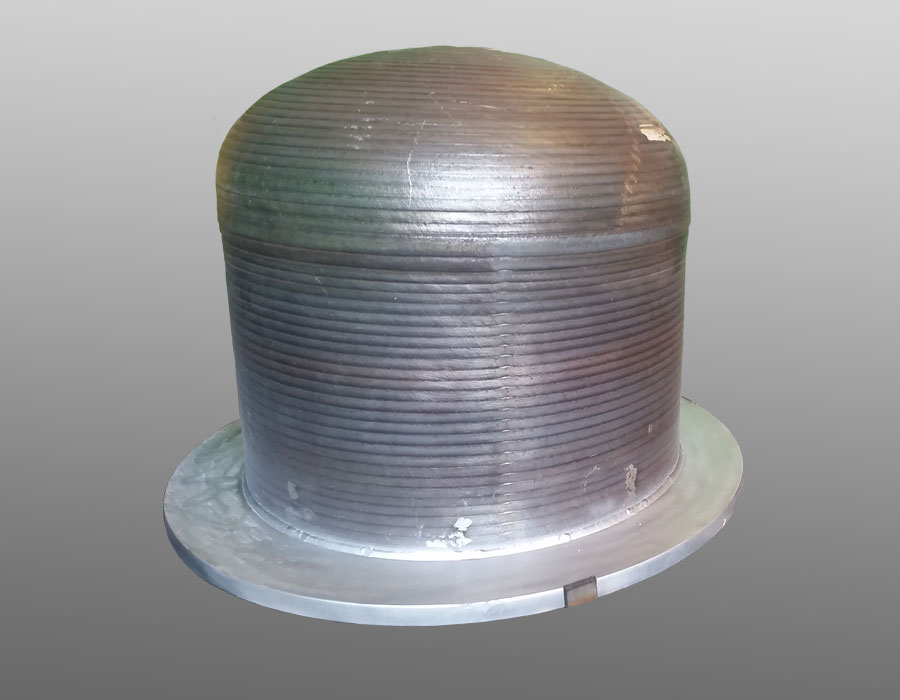

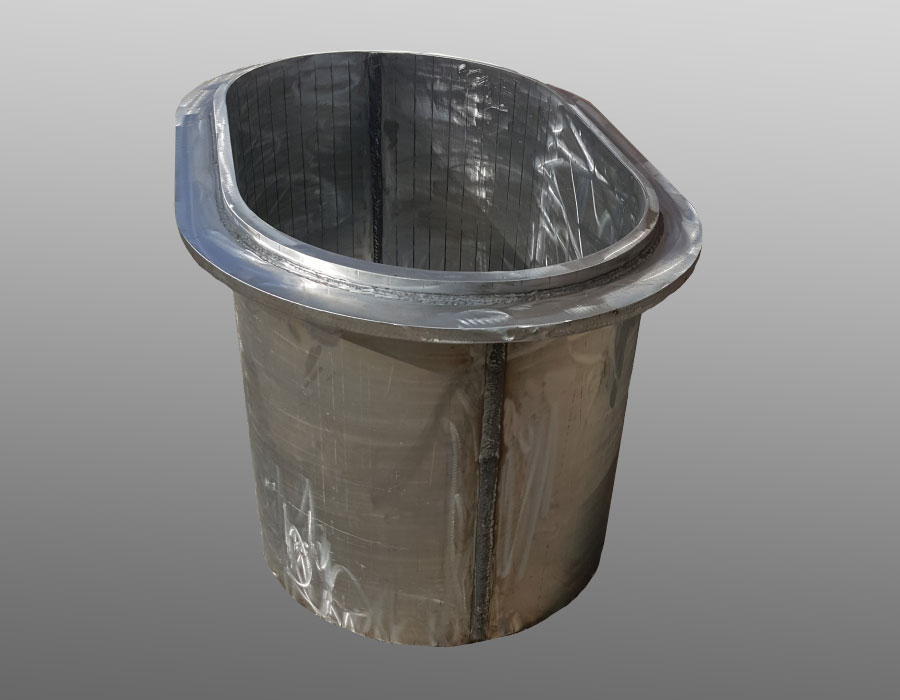

Crucibles for magnesium alloys, in various sizes with a capacity ranging from 10 to 15000 kg, for hot chamber and cold chamber die casting, as well as for furnaces for holding, remelting and recycling.

In 1965, the company began to specialize in the manufacture of crucibles for magnesium alloys. Since then, much research has been done to continuously improve this type of crucible in order to meet customers’ changing needs and to increasingly adapt the crucibles to the new alloys and technologies that have recently emerged on the market.

In the last 10 years, Musto et Bureau S.r.l. has been committed to researching and studying increasingly high-performance materials, ranging from basic materials to materials used in external and internal cladding, as well as those used in flanges. Thanks to recently acquired tools and to new production processes, Musto et Bureau S.r.l. is able to offer increasingly efficient and competitive products and a wide range of crucibles, ranging from the supply of the standardized model for machines that are already present on the market to the design of custom crucibles.

Thanks to the experience that the company has acquired over the years, Musto et Bureau S.r.l. is now able to provide technical assistance on systems and to foundries’ various production stages, as well as support for the implementation of turnkey projects.

Crucibles can be produced in the most varied shapes and sizes, with capacities ranging from 10 to 15000 kg for all types of casting:

- Hot chamber and cold chamber die casting

- Sand casting

- Shell-mould casting

- Gravity casting

- Remelting

- Recycling